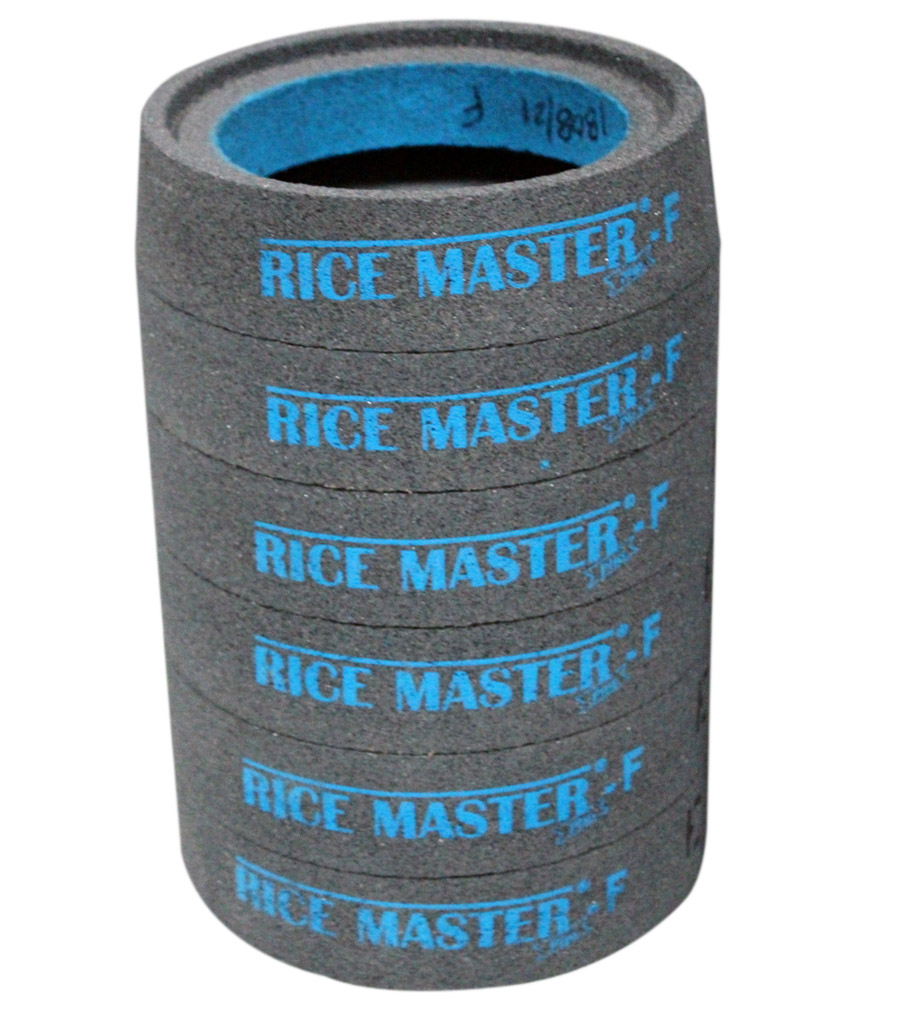

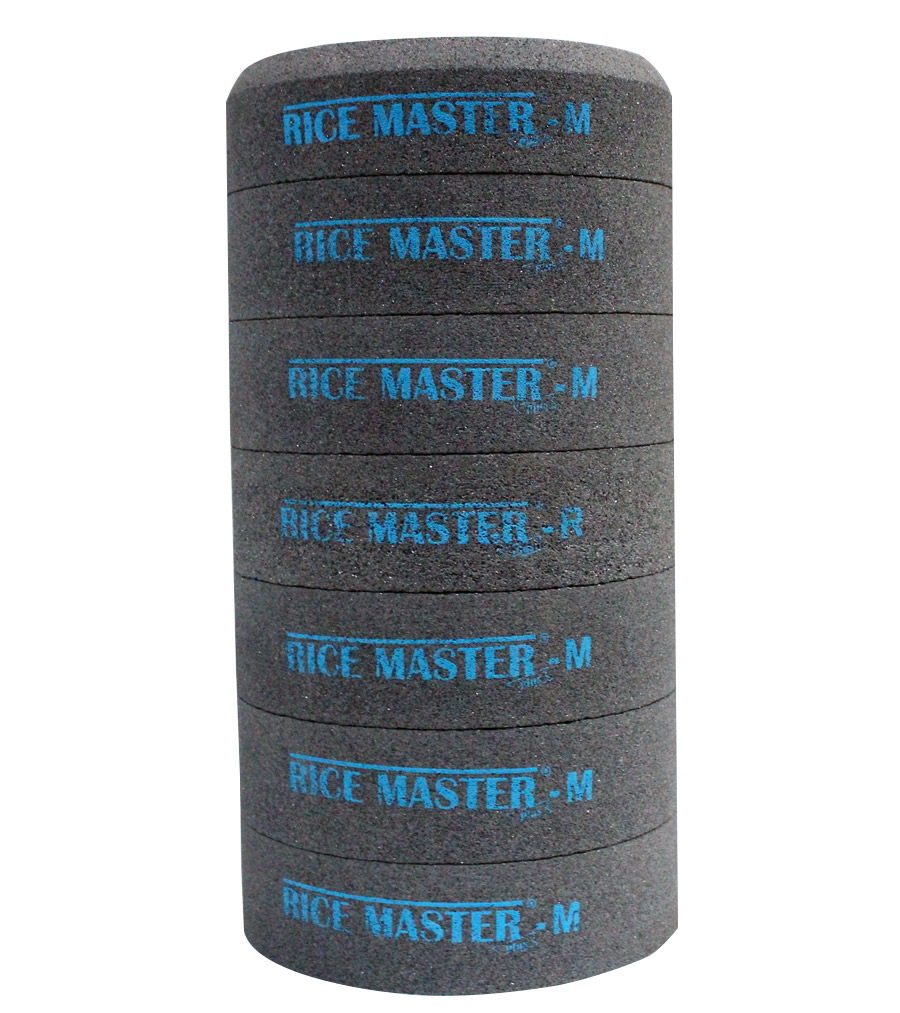

Rice Master Plus

Rice Master is 40 years old product that has evolved with Sterling Abrasive’s experience of hundreds of clients in the rice industry. The product enjoys a special edge in the market where the client is keen on maximizing his profits by gaining not only the full rice but also a standard quality.

Salient Feature

- Minimum rice brokens.

- Better whiteness & shining on rice.

- Longer operational life of stone due to imported raw material used.

- Reduction in electricity consumption.

- Easy fitment of stone due to close dimensional accuracy achieved on CNC machineries.

- All abrasive roller pieces are precisely balanced.

- Can be supplied with metal flange and Hub.